Intermediate result from partner Neste, Mol and OWI

Result has been achieved in December 2019 in month 15 of the project.

Formulated Redifuel consists of 30 vol % of liner alcohols (C6 – C11) and 70 vol % of gas to liquid fuels (GtL). A detailed analysis of Redifuel as well as its blends with EN590 diesel has been performed to ensure their compliance with EN590 standards. Obtained analytics throw a light on various crucial physical and chemical properties of these fuels.

- Objective: To perform a detailed analysis on various physical and chemical properties of Redifuel mixtures and evaluate their potential to be renewable drop-in capable and EN590 compliant fuels based on the obtained results.

- Research: The potential of Redifuel and proposed blends as drop-in diesel was evaluated based on the performed analysis. A comprehensive set of physical and chemical properties (~30) was considered for the analysis.

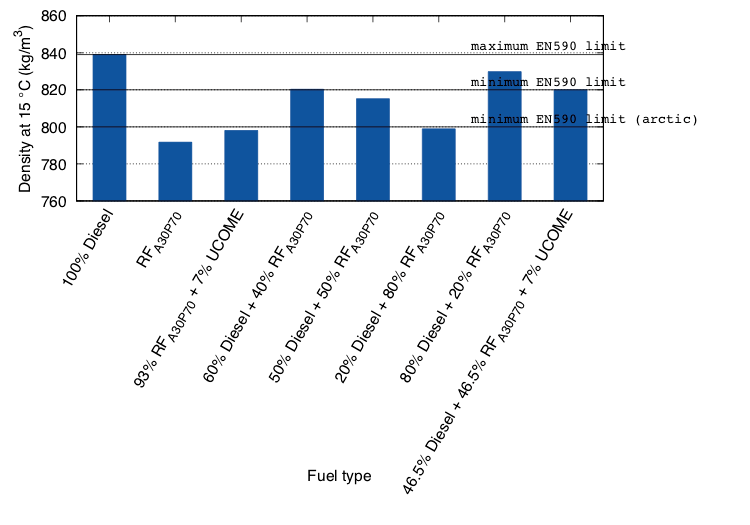

- Result: For analyzed Redifuel and their blends, Cetane number and conductivity is within the range of EN590 specifications. Hence, any cetane improver and conductivity additive is not required. Lubricity additives and cold flow improvers are needed since CFPP and HFRR are not within the EN590 standards. The effect of CFPP additive and lubricity improver on Redifuel and its blends were studied and their responses are comparable to their behavior when added in fossil diesel. Two main concerns observed with the proposed fuels are density and water content. Hence, incorporation of 7 vol % UCOME in the mixture is seen to be crucial and the density of Redifuel/UCOME (798 kg/m3) blend is very close to the minimum Nordic EN590 density limit (800 kg/m3). Water content in all blends is much higher than the EN590 limit. This high water content is not expected to have any big impact on the suitable operation (combustion) of these fuels in practical engine, although it is much beyond the EN590 limit.

- What will it be used for: The analytical results were shared with other partners and mainly contribute to the identification of the most suitable renewable drop-in diesel.

- Impact: The performed fuel analyses reveal that Redifuel is capable of fulfilling most of the EN590 requirements on fuel quality with or even without additives. Furthermore, conventional additives for fossil diesel fuel can be utilized for Redifuel. As the density of the formulated fuel is not as high as EN590 reference diesel, blending with UCOME is essential for the final fuel blend.

Figure 1: Density of Redifuel and all proposed blends in comparison to EN590 grade diesel