Intermediate result from partners CSIC, MPI-CEC

Result has been achieved on14 January 2019 in month 9 of the project.

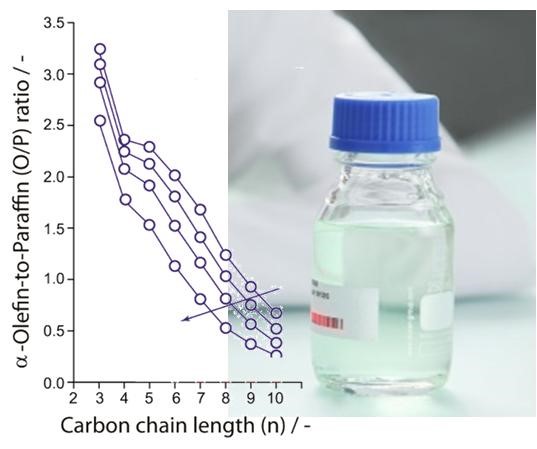

A mixture of C5-C10 straight-chain olefins (terminal and internal) and paraffins has been produced synthetically in the lab, using high-purity commercial components. The composition of this mixture simulates that of a C5-C10 product cut obtained from the Fischer-Tropsch (FT) catalytic conversion of biosyngas with the 1st generation FT catalysts in the tests performed in the lab under industrially relevant conditions. The liquid hydrocarbon mixture is going to be used as a surrogate for the FT product cut, acting as feed for the olefin hydroformylation catalysts and processes at the MPI partner.

- Objective: To provide a surrogate C5-C10 hydrocarbon mixture as a suitable replacement for the corresponding FT C5-C10 product cut, in order to enable relevant olefin hydroformylation catalyst- and process developments prior to the availability of the real FT product cut expected from upscaling and demonstration activities later in the project.

- Research: The composition of the FT cut was determined from experimental tests of the 1st generation FT catalysts employed by the consortium (developed by the CSIC partner) and the known ASF mathematical chain-lengths distribution associated to the polymerization kinetics of the FT reaction. Commercial hydrocarbons were then blended in the liquid phase to attain the desired mixture composition.

- Result: Circa 150 mL of the surrogate C5-C10 FT product cut surrogate.

- What will it be used for: Olefin hydroformylation catalyst and process development at lab- and miniplant scales.

- Impact: The development of this surrogate mixture enables progress around the hydroformylation process to set in before real FT products are obtained in the context of piloting activities.

Image: (left) Olefin-to-paraffin product distribution in the C3-C10 hydrocarbon fraction obtained, at different biosyngas conversion levels (increasing as indicated with the arrow) as used as reference to generate the synthetic C5-C10 FT product cut surrogate mixture (right)