Intermediate result from partner VKA-RWTH and OWI

Result has been achieved on 15 December 2019 in month 15 of the project.

The final REDIFUEL end-product targets a biofuel with a maximum of 30 vol% C6-C11 alcohols mixture and 70 vol% hydrocarbons (paraffinic diesel). Since at the beginning of the project the real-end product is available only on lab-scale, a surrogate alcohol mixture (SAM) is prepared with pure components to conduct the experimental work and GtL is chosen to represent the bio-paraffinic content of REDIFUEL. Due to the complex multi-component nature of REDIFUEL a surrogate approach was established to model the thermo-physical (i.e., specific heat capacity, thermal conductivity, and heat of vaporization) and physicochemical properties (i.e., viscosity, density, and surface tension) in a simple manner in 3D-CFD simulations. These properties are pivotal to model droplet break-up and consequent evaporation, which are fundamental for the in-cylinder phenomena affecting combustion and emissions. These properties are necessary over a wide range of temperatures, i.e. from the melting temperature (Tm) to the critical temperature (Tc) and can be estimated using prediction models found in previous literature works, and validated with the help of experimental data shared by the OWI Science for Fuels GmbH.

- Objective: To estimate the thermo-physical and physicochemical properties of REDIFUEL.

- Research: The density and viscosity are measured in accordance with DIN EN ISO 12185:1996 with a Stabinger Viscometer (SVMTM 3001) at OWI over a temperature range of 288 K to 398 K. These measurement results are used to validate the surrogate approach shown here.

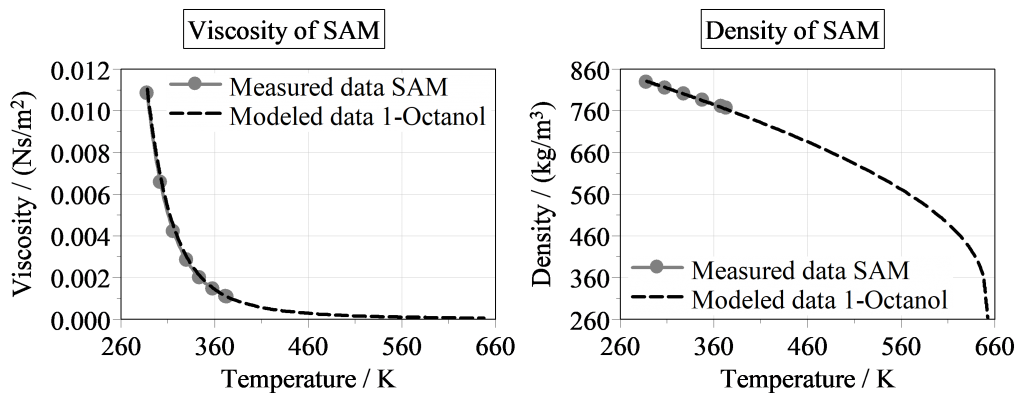

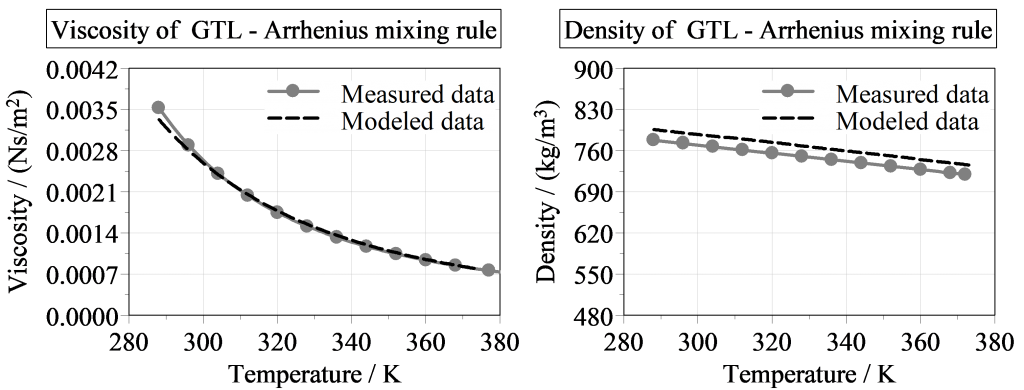

- Result: Figure 1 presents a comparison of the measured viscosity and density of SAM v/s the modeled data of 1-octanol. This fuel was proposed as a possible representative of the SAM since its molecular composition lies in the middle of the C6-C11 alcohols. For the estimation of dynamic viscosity and density, the Andrade and Yaw’s regression equation was used, respectively. It can be observed that the modeled data of 1-octanol shows a very good agreement with the measured SAM data. Hence, 1-octanol is a valid surrogate for the SAM. The same model parameters were used to extrapolate the data in the higher temperatures range. For GtL a surrogate ternary mixture found in previous literature work was chosen (i.e., 45 vol% cyclo-octane, 51 vol% iso-cetane and 4 vol% n-decane) and an Arrhenius mixing rule was adopted to predict a given physical property. Figure 2 shows the comparison between measured and modeled viscosity and density of GtL. Here, it can be noticed that both modeled properties match well with the measured ones.

- What will it be used for: The estimated fuel properties will be used as input for the numerical modeling of mixture formation (3D-CFD simulations).

- Impact: The multi-component complex mixture as REDIFUEL can be simulated with few selected compounds. This helps the characterization of REDIFUEL and conducting a more in-depth analysis on material compatibility, engine testing etc. Moreover, it allows to simulate cold and hot evaporative conditions and perform an in-cylinder assessment of the fuel via 3D-CFD simulations.

Figure 1: Comparison of measured viscosity and density of the surrogate alcohol mixture (SAM) with modeled viscosity and density of 1-octanol (VKA-RWTH and OWI)

Figure 2: Comparison of measured GtL viscosity and density with its surrogate modeled fuel mixture of 45 vol% cyclo-octane, 51 vol% iso-cetane and 4 vol% n-decane (VKA-RWTH and OWI)