Intermediate result from partner VUB

Result has been achieved on 25 June 2020 in month 21 of the project.

In order to compare the energetic performance of REDIFUEL to other commercial fuels, a literature review was done on the state-of-the-art of energetic performance of fuels.

- Objective: Establishing a benchmark on energy efficiency for comparison of REDIFUEL with fossil-, bio- and e-fuels.

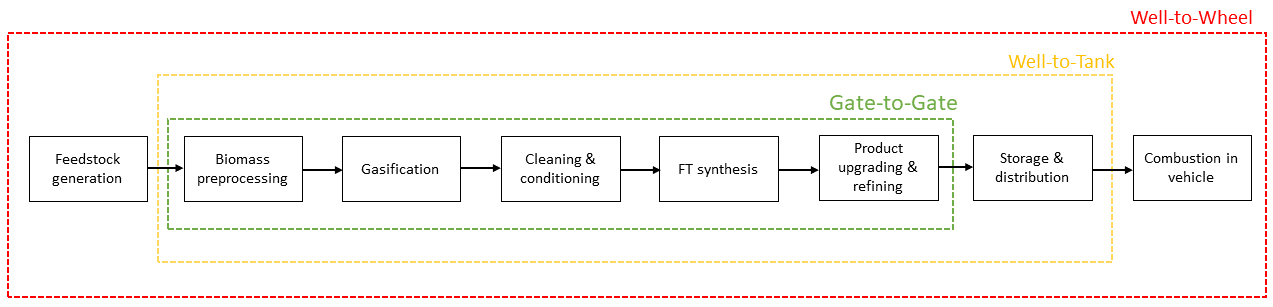

- Research: A literature review was done on the state-of-the-art of energy efficiency of fossil-, bio- and e-fuels. This was done on two levels, and a third level is ongoing (Figure 1):

- Gate–to-gate level for the overall plant and liquid fuel efficiency of Fischer-Tropsch plants. 45 estimates of energy conversion efficiency have been identified and analyzed.

- Well-to-tank level for the energy expended in the production and distribution of fossil diesel, Fischer-Tropsch diesel and biodiesel.

- Well-to-wheel level (ongoing) for the energy expended in the production, distribution and combustion of various fuels.

- Results:

- The overall plant efficiency of Fischer-Tropsch plants (gate-to-gate) with dual fluidized bed gasifiers ranges from 28-72% and this efficiency is greatly dependent on how well waste heat is valorized and heat losses are minimalized by system integration.

- The liquid fuel efficiency of these plants, i.e. the biomass-to-fuel efficiency, ranges from 18-33%. This efficiency is highly dependent on the moisture content of the feedstock. Feedstocks should therefore be dried as thoroughly as possible.

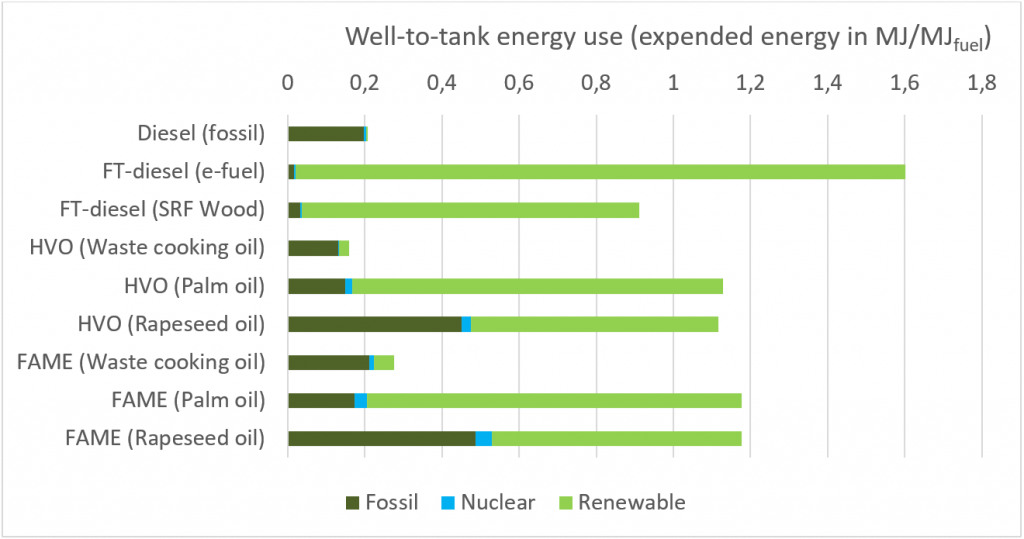

- The well-to-tank energy use of Fischer-Tropsch fuels is relatively high compared to other fuels. However, they perform better than first generation biodiesel (e.g. from rapeseed oil or palm oil). The production pathways of e-fuels are inefficient, but they can contribute to the overall efficiency of the EU energy system by storing surplus electricity into high density fuels.

- What will it be used for: The results will be used to assess the performance of REDIFUEL compared to other known fuels.

- Impact: This benchmark will contribute to the total evaluation of REDIFUEL and can be determining for future investments.

Figure 1: Different system boundaries for energy efficiency analysis on Fischer-Tropsch (FT) fuel production. In this project, the gate-to-gate system boundary is used for energy conversion efficiency calculations for comparison between different FT plants. The well-to-tank and well-to-wheel system boundaries are used for energy use calculations to compare between different fuels.

Figure 2: Well-to-tank expended energy by energy source of fossil diesel and several biodiesel alternatives. The FT-diesel (e-fuel) pathway considers FT-diesel production from green hydrogen and absorbed CO2 from industrial flue gasses. SRF stands for short rotation forestry and this pathway considers FT-diesel production from energy crops such as poplar and willow. HVO stands for hydrotreated vegetable oil and FAME stands for fatty acid methyl ester. For these types of biodiesel three different feedstocks have been selected. Adapted from JEC well-to-tank report (2013).