Intermediate result from partner VKA-RWTH

Effect of fuel formulation on the mixture formation and engine performance

Result has been achieved on 11 October 2020 in month 25 of the project.

To evaluate the mixture formation and emissions reduction potential of REDIFUEL, three-dimensional computational fluid dynamic (3D-CFD) simulations were performed. The different blend of diesel and surrogate alcohol mixture (SAM) with gas to liquid (GtL) of the RFA30P70 (i.e., 30 vol% alcohols mixed with paraffinic diesel) were simulated here. Due to the complex multi-component nature of REDIFUEL a surrogate approach was established to model the thermo-physical and physicochemical properties in a simple manner in 3D-CFD simulations. Two different blends of RFA30P70 with diesel (B0) were studied. The first blend of 60 vol% B0 and 40 vol% RFA30P70 was selected, owing to is CN and density meeting the EN590 norm. Furthermore, a second blend, having fully renewable fuel 93 vol % RFA30P70, was simulated to derive trends for fully renewable substitution share in the fuel mixture.

- Objective: To evaluate the mixture formation and emissions reduction potential of REDIFUEL.

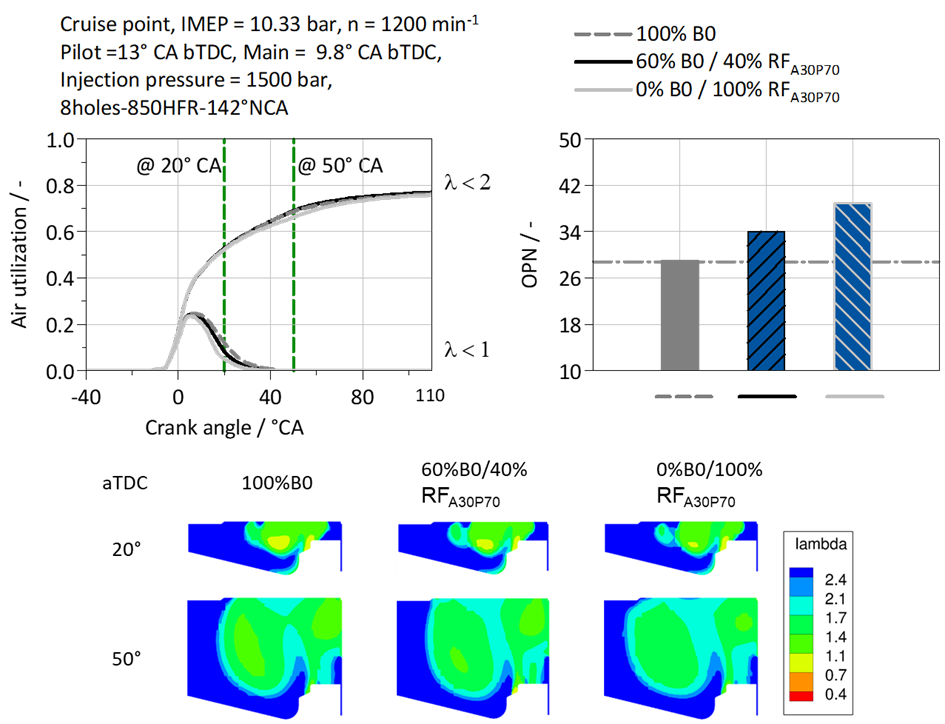

- Research: Reynolds-averaged Navier–Stokes numerical simulations were performed using the CFD code provided by CONVERGE. CONVERGE is a general-purpose CFD tool that automates the mesh generation process and the adaptive mesh refinement algorithm. The mixture formation during the high-pressure cycle under inert mixing condition was analyzed. In a first step, the CFD model was calibrated against diesel experimental data from the heavy duty single cylinder engine (HD SCE) at cruise point operation to ensure modeling with a good confidence level. Here, ignition and combustion were modeled and captured with high accuracy. In a second step, the physico-chemical properties of diesel were exchanged with those of the blend of RFA30P70 and B0 and the simulations were re-run under inert air/fuel mixing conditions. This step was necessary since no available reaction kinetics model was available to model the RFA30P70.To assess the quality of the mixture formation process the characteristic numbers Air Utilisation (AU) and Oxidation Potential Number (OPN) were used. The AU indicates the volumetric fraction of air inside the combustion chamber, sorted per air/fuel equivalence ratios (λ) ranges. The AU is evaluated at a given engine operating condition, from starting of injection (SOI) to exhaust valve opening (EVO). The OPN is a number based on the AU. It represents the share of the lean mixture (i.e. Air utilization between 1 < 𝜆 < 2) divided by the rich one (𝜆 < 1) and by the unused air (𝜆 > 2). The OPN aims at capturing the soot oxidation potential and higher is the OPN a better mixture formation is expectable.

- Results: Figure 1 (top) presents the comparison of the AU and OPN for different blends of RFA30P70 and diesel at cruise point operation. It can be seen that with an increasing blending proportion of RFA30P70 in diesel, the share of a lean mixture (i.e. AU between 1 < 𝜆 < 2) is larger. Hence, a higher degree of air/fuel mixing and a high potential to oxidize soot during combustion is expected. Further, the RFA30P70 blends resulted in higher OPN as compared to diesel. An increase in OPN represents a high potential to oxidize soot. The bottom of Figure 1 shows the cut-sections of the piston bowl modeled in CONVERGE that corroborate the trends of the air utilization curves. At the selected crank angle of 22 °CA and 50 °CA a larger share of lean equivalence ratios can be seen and a smaller share of rich zones (𝜆 < 1). This indicates that the soot is expected to be better oxidized in case of the blends with RFA30P70. With improvements in the air/fuel mixing process, it is expected to have better overall combustion and which will improve the.engine performance.

- What will it be used for: The results will be input for combustion system optimization of the heavy duty single cylinder engine.

- Impact: The blends of REDIFUEL with diesel showed enhanced mixture formation, as indicated also by a higher level of oxygen entrainment in the spray plume as compared to diesel.This indicates a better soot oxidation potential of the REDIFUEL blends, which was also corroborated during the HD SCE testing conducted by the cooperation partner FEV.

Figure 1: Comparison of air utilization and OPN (ref. 1, top), and lambda plots for RFA30P70 and diesel (ref. 1, bottom), at cruise point (VKA-RWTH)