Intermediate result from partner MPI-CEC

Pilot Plant Design, Construction and Testing for the Hydroformylation of Fischer-Tropsch Type Olefin Paraffin Mixtures

Result has been achieved on 23 August 2020 in month 23 of the project.

In the hydroformylation process a biphasic liquid/liquid reaction system is used. This reaction system allows an easy and efficient catalyst recycling with simultaneous high activity. However this also places special demands for a continuous process. To achieve high reaction speeds, an intense mixing of the two liquid phases is necessary. Following the reaction, the phases need to be separated afterwards in order to withdraw the product and recycle the catalyst phase back to the reactor.

A continuous miniplant was designed and constructed fulfilling all these requirements. The used reactor is a Continuously-Stirred-Tank-Reactor (CSTR) which allows for both, high energy inputs and the use of optimized stirrer geometries. This guarantees optimal mixing of the two phases. In line with the reactor, a settler unit allows for a continuous separation of the two phases after the reaction. The Reactor and Settler have been connected in series and automated for a continuous operation.

- Objective: The design and construction of a reactor/settler minplant for the continuous hydroformylation of Fischer-Tropsch mixtures.

- Research: A Continuously-Stirred-Tank-Reactor dedicated to the hydroformylation of Fischer-Tropsch mixtures which allows for high energy inputs was designed and constructed. A settler unit for a continuous withdrawing of synthesized products was connected to the reactor.

- Results: The reactor/settler setup was constructed and automatized. First tests with 24 hours of continuous operation, with 1-octene as model substrate, have been performed. No technical issues occurred during those tests. The hydroformylation products were successfully separated from the catalyst in the settler and almost no loss of catalyst was observed.

- What will it be used for: In the future, this minplant setup will be used for the continuous hydroformylation of various Fischer-Tropsch mixtures.

- Impact: The successful operation of the miniplant shows that the reactor design and the automation are well suited for the hydroformylation reaction in a biphasic system. The next step will be the transformation of real Fischer-Tropsch mixtures from the project partner VTT.

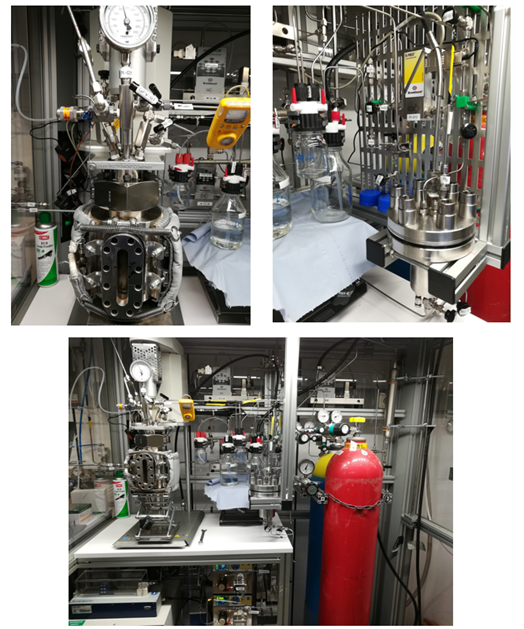

Figure 1: Miniplant setup for the continuous hydroformylation: (top left) 200 mL window reactor, (top right) settler unit for the continuous withdrawing of products, (bootom) reactor/settler setup and associated equipment.