Intermediate result from partner FEV

Result has been achieved on 28 January 2020 in month 16 of the project.

Highly efficient engines are needed to comply with current carbon dioxide (CO2) limits. As the transport sector significantly contributes to anthropogenic air pollution and CO2 and the depletion of fossil resources is inevitable, sustainable energy carriers with a low greenhouse-gas footprint represent an attractive alternative. A heavy duty single cylinder diesel engine (HD-SCE) was used to assess the impact on engine performance of several renewable drop-in mixtures. The fuels have a paraffinic and oxygenated content, which targets the end-product realized via Fischer-Tropsch synthesis and hydroformylation. The surrogate of the REDIFUEL had 30 vol% a C6-C11 alcohol mixture and 70 vol% GtL and it was termed RFA30P70. Different blending proportions with diesel were tested, to assess their impact on engine out emissions and indicated thermal efficiency (ITE). Additionally, a fully renewable fuel also compliant with the EN590 norm, obtained adding 7 vol% Used Cooking Oil Methyl Ester (UCOME) to RFA30P70, was investigated too.

- Objective: In-engine assessment of the most promising drop-in blend and/or neat renewable REDIFUEL.

- Research: Benefits in engine efficiency and pollutant emissions were investigated on the HD-SCE and put in context with well-to-tank CO2 emissions. Each fuel was bench marked against diesel (EN590) at selected engine load points, best representing the boundary conditions within current emissions regulation cycles. The tests were conducted with constant engine calibration parameters at same combustion center, to minimize the impact of combustion shifts due to a different self-ignition tendency on emissions. Exhaust gas re-circulation sweeps were conducted to test the fuels at same EURO VI nitrogen oxides (NOX) as diesel.

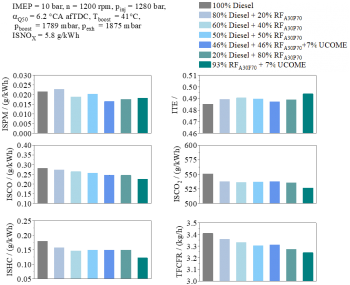

- Result: Generally, the IS particulate matter (PM), carbon monoxide (CO) and hydrocarbon (HC) emissions diminish and the ITE improves with increasing RFA30P70 share in diesel (Figure 1). The EN590-compliant blend with 40 vol% RFA30P70 mixed in diesel exhibit a relative reduction in ISPM, ISCO; ISHC, and ISCO2 by 12 %, 6 %, 18 %, and 2.6 % respectively, when compared to diesel. The changes in ISCO2 can be explained with the theoretical fuel carbon mass fraction (TFCF). It is the carbon mass flow rate available for a complete combustion of a fuel at a given engine load, accounting for changes in fuel heating value and ITE. A reduction by 2.3 % for the blend under analysis can be seen and it nearly agrees with the relative ISCO2 reduction. The fully renewable REDIFUEL mixture with 7 vol% UCOME, meeting the lower density limit for artic grading (i.e. 800 kg/m3 at 15°C), exhibits a relative reduction in ISPM, ISCO; ISHC, and ISCO2 by 15.3 %, 19.9 %, 32.2 %, and 4.4 %, respectively when compared to diesel. Moreover, a maximum ITE gain up to ~1.8% relative to the diesel baseline was observed too.

- What will it be used for: The results were shared and discussed with the REDIFUEL partners to define the next steps.

- Impact: The EN590-compliant blend of 40 vol% RFA30P7o in diesel is an attractive measure to reduce CO2 emissions in the near future. Hence, it is selected to conduct a more complete engine screening and for the demonstrator vehicle tests. Nevertheless, the truck will also be fueled with the fully renewable REDIFUEL blend, to exploit the maximum CO2 well-to-wheel benefit.

Figure 1: Engine out emissions, indicated thermal efficiency and theoretical fuel carbon fraction for the REDIFUEL blends with diesel tested at EURO VI ISNOx of 6 g/kWh at 10 bar indicated mean effective pressure under 1200 min-1 engine speed.